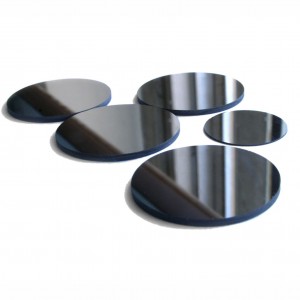

Polycrystalline Cubic Boron Nitride (PCBN) fun Awọn ohun elo Ṣiṣepo

PCBN composites ti wa ni produced nipa sintering micron CBN lulú pẹlu orisirisi seramiki, ki o le gbe awọn lalailopinpin lile ati ki o gbona ohun elo irinṣẹ Pupọ PCBN ohun elo ti wa ni integrally iwe adehun si kan cemented carbide sobusitireti.CBN jẹ ohun elo keji ti o nira julọ ti a mọ lẹhin diamond sintetiki, ṣugbọn o ni igbona giga ati awọn ohun-ini resistance kemikali.O ti wa ni o kun lo ninu gige ati processing ti ga líle tabi soro lati lọwọ awọn ohun elo pẹlu lile, irin, grẹy ati ki o ga agbara simẹnti irin, ga iyara irin, simẹnti irin quench alloy, sintering irin ohun elo, ati be be lo.

| Koodu # | Iwọn opin (mm) | Layer Diamond (mm) | Giga(mm) | Abrasive ratio | Ẹya ara ẹrọ | Ohun elo |

| HC1303 | 13.5 | 0.8-1.0 | 3.2 | > 10000 |

CBN Layer ati Wc-co sobusitireti High CBN akoonu 2. Iwọn resistance to gaju 3. Agbara rupture ti o dara 4.Good iduroṣinṣin kemikali | 1. kongẹ dimension2.Simẹnti grẹy Iron3.Agbara irin4.Ooru koju 5. Quench alloy 6. Irin irin & kú irin |

| HCF1304 | 13.5 | 0.8-1.0 | 4.5 | |||

| HC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| HC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| HC3203 | 32.0 | 0.8-1.0 | 3.2 | |||

| LC1303 | 13.5 | 0.8-1.0 | 3.2 | > 3000-4000 |

CBN Layer ati Wc-co sobusitireti 2. Jo kekere akoonu CBN 3. Ga yiya ratio 4. Ti o dara egboogi-rupture agbara |

metallurgy awọn ẹya ara |

| LC1304 | 13.5 | 0.8-1.0 | 4.0 | |||

| LC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| LC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| LC3203 | 32.0 | 0.6-0.8 | 3.2 | |||

| HB0903 | 9.55 | 3.18 | 3.18 | > 5000 |

|

|

| HB1204 | 12.7 | 4.76 | 4.76 | |||

| HB1608 | 15.85 | 8.0 | 8.0 | |||

| HB2008 | 20.0 | 8.0 | 8.0 |