CCS25 Cu Co Sn Prealloyed Powder fun Didara Marble ri Blade

CCS25 Cu Co Sn Prealloyed Powder fun Didara Marble ri Blade

1. Kini Pre-alloyed Powder

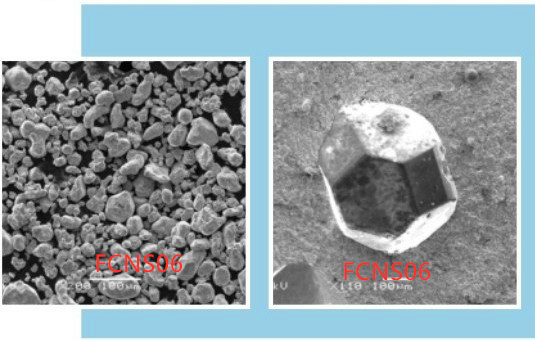

Awọn erupẹ alloyed ti o ṣaju jẹ lile, kere si compressible ati nitorinaa nilo awọn ẹru titẹ ti o ga lati gbe awọn iwapọ iwuwo giga.Sibẹsibẹ, wọn ni agbara lati ṣe agbejade awọn ohun elo ti o ni agbara giga.Iṣaaju-alloying tun jẹ lilo nigbati iṣelọpọ ohun elo isokan lati awọn erupẹ ipilẹ nilo awọn iwọn otutu ti o ga pupọ ati awọn akoko isunmọ gigun.Awọn apẹẹrẹ ti o dara julọ ni awọn irin alagbara, ti chromium ati awọn akoonu nickel gbọdọ wa ni iṣaaju-alloyed lati gba iṣelọpọ aje nipasẹ irin-irin lulú.

2. Awọn paramita ti CCS25

| Akọkọ Ano | Ku, Co, Sn |

| O tumq si iwuwo | 8.29g/cm³ | |

| Sintering otutu | 760℃ | |

| Titẹ Agbara | 800Mpa | |

| Lile | 85-95HRB |

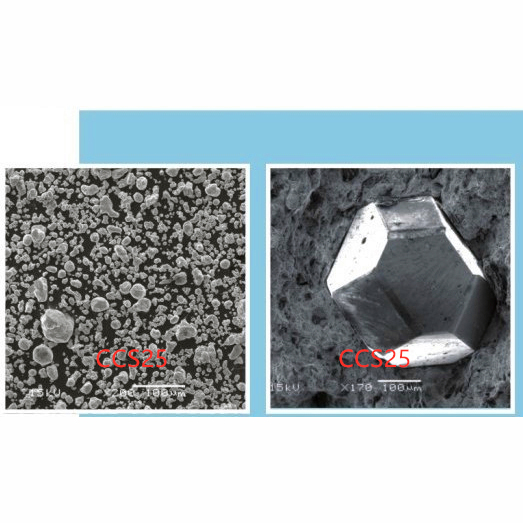

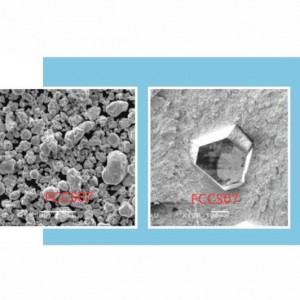

3. CCS25 Pre-alloyed Powder Character

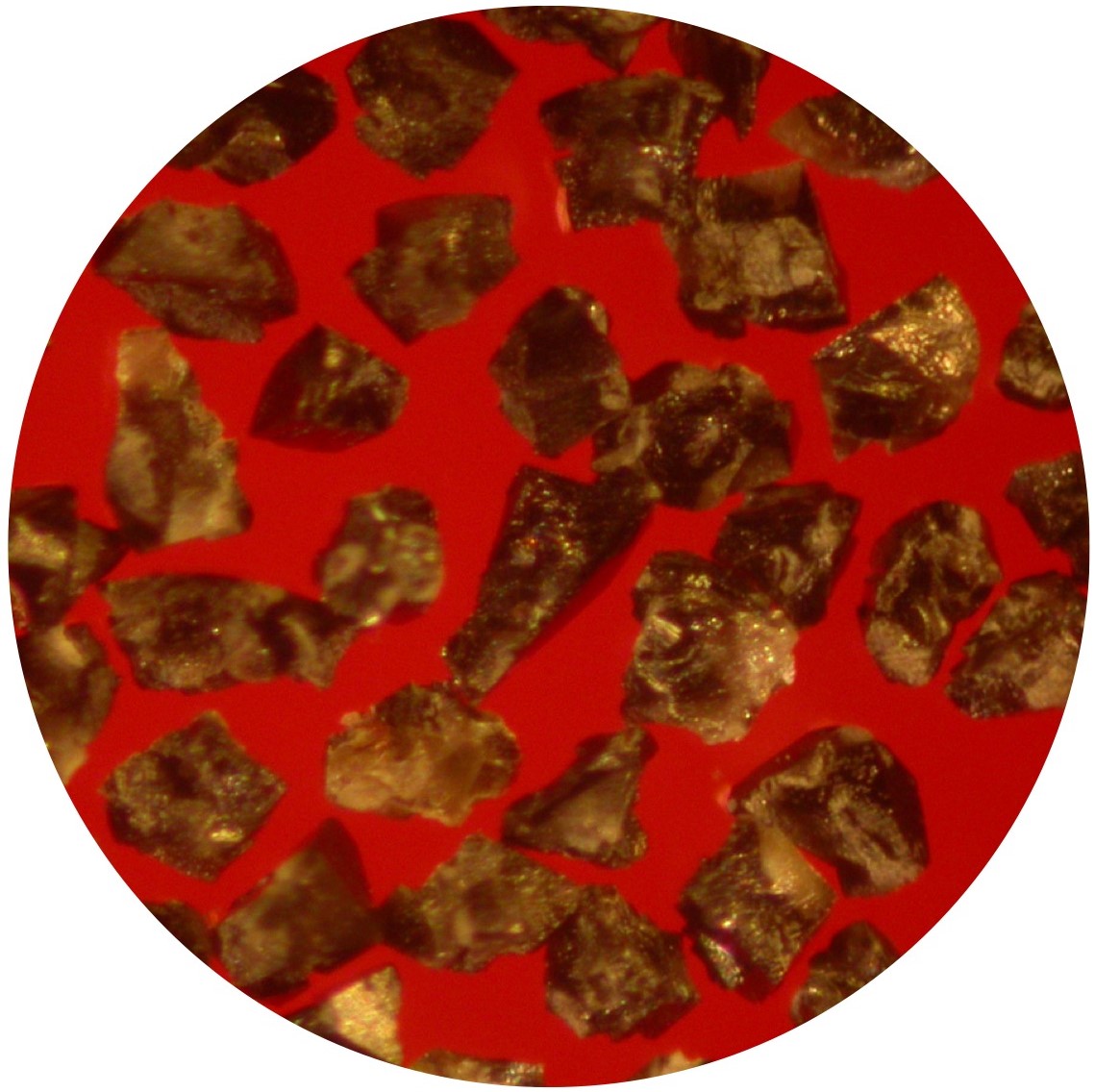

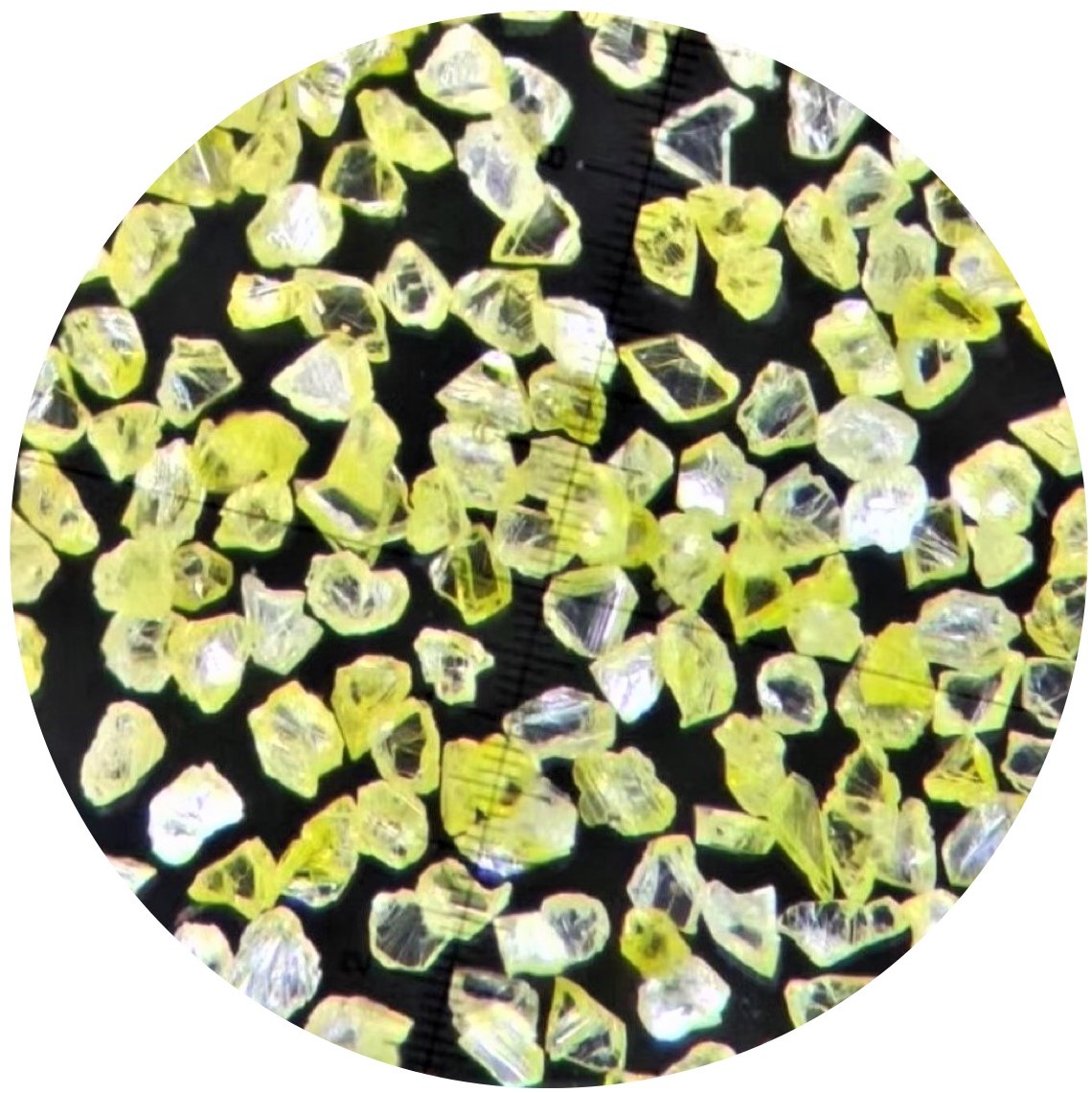

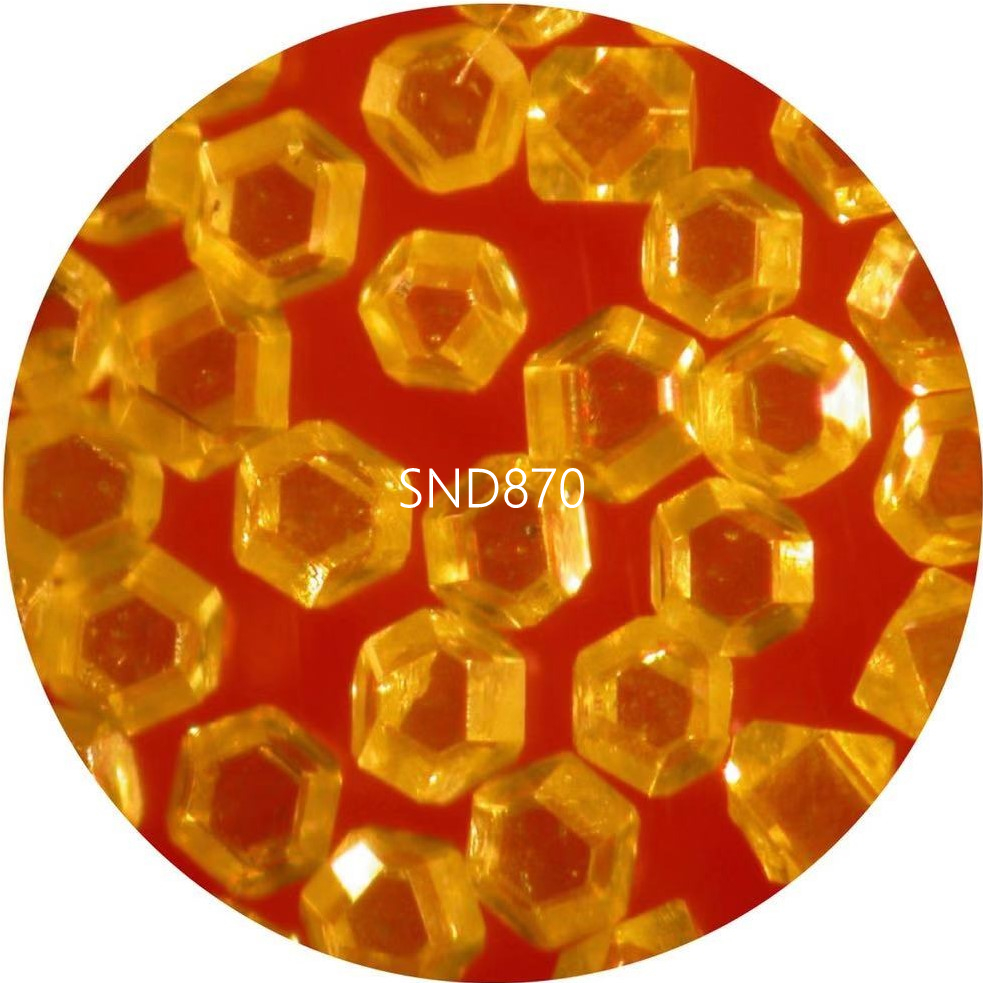

- Ẹya Sintered ti ọja naa jẹ aṣọ-aṣọ, ti o dara ati iwapọ, diamond ti wa ni tutu ati ti ẹrọ ti a we.Ohun kikọ akọkọ mnu jẹ “alakikanju & Friagility”, resistance yiya nla ati iṣẹ didara okeerẹ.

- Ti a lo si alabọde si abẹfẹlẹ didan didara giga, kẹkẹ lilọ gilasi.

4. Ilana Lilo fun Mrable ri Blade

- Irin Lulú

- 50-70% CCS25

- + 25-35% Cu

- + 4-7% Sn

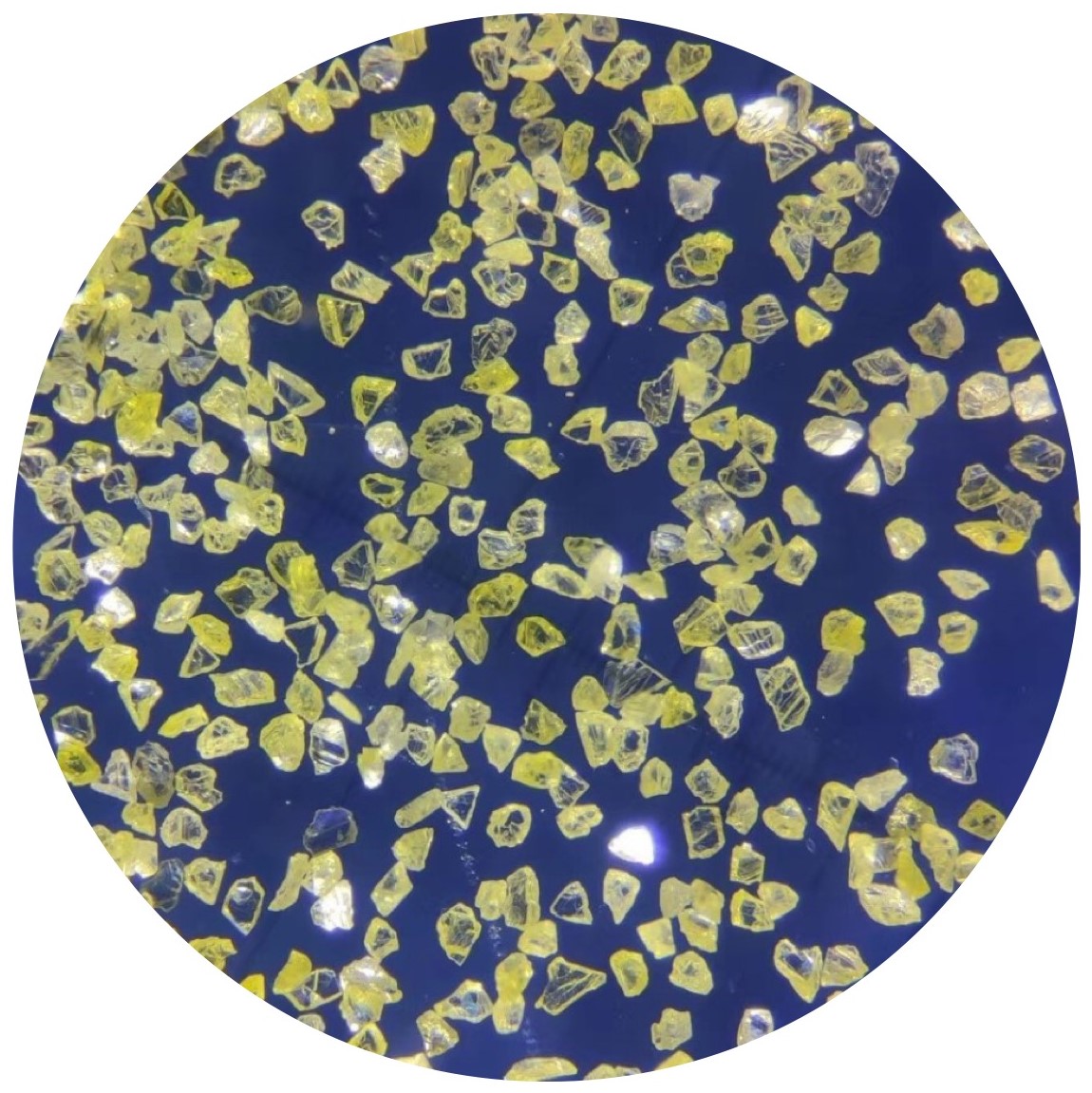

B. Diamond

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @ 30%

- Ifojusi Diamond @ 20-25%

C. Sintering otutu 760-780 ℃

Kọ ifiranṣẹ rẹ nibi ki o si fi si wa